360.261.0341

5321 NE 30th Ave., Vancouver, WA 98663

By Appointment Only

Rick Reiss, Luthier

Authorized Warranty Service for C. F. Martin Guitar Co. and Taylor Guitars

Luthiers summary: Instrument, 1930's Washburn flattop acoustic. This bridge pin rout and plug procedure is documented after I've already rerouted the saddle slot. I also minimally resurfaced the top of the bridge, to give it a face-lift essentially. I neglected to take before pictures to document the original damage and scarring from previous "do it yourself...repairs".

It is important to note that routing the bridge pin slots and plugging them, achieves a more obtuse "break angle". That is the primary objective for this procedure. This creates more of a downward pressure (perpendicular to the plane of the top) from the strings, as opposed to a linear tension (towards the nut). The slots cut from the bridge pin holes caused the string to exit too close to the saddle. I'm also resetting the neck angle of the guitar after the bridge restoration is completed. The wood of the guitar distorts over time causing the string height to rise. Eventually, over 40 years or so, (give or take a decade or two) the saddle is repeatedly lowered and the holes are repeatedly slotted, to maintain a decent string pressure across the saddle. When resetting the neck angle of the guitar, the two common primary objectives are: to lower the strings and make them closer to the frets for a desirable string height, and to increase the height of the saddle at the same time.

The height of the saddle is critically important for proper projection of sound. If the saddle has become too short over time, the lack of leverage or torque to the top, will not agitate the surface area of the instrument sufficiently, resulting in a weak or quiet voice. If the height of the saddle is increased without this routing procedure, the front of the bridge (especially a bridge with a long slot design like this, and many vintage guitars) can quite easily crack off.

You can refer to the difference in the height of the 12 string saddle pictures in the "Sounds Better" section of the site, to get a clearer idea of the principle.

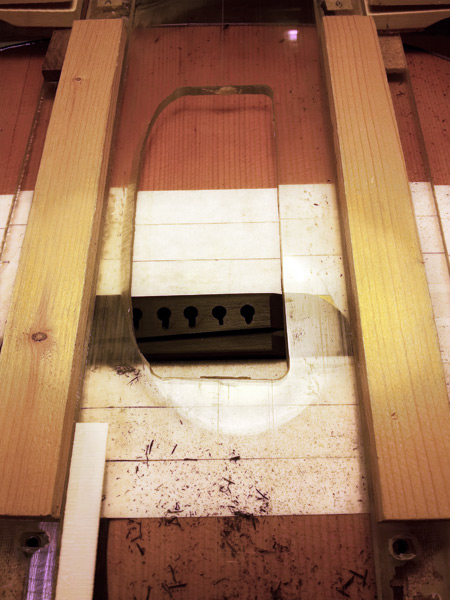

This shows the "original" slots that were cut towards the saddle from the bridge pin holes.

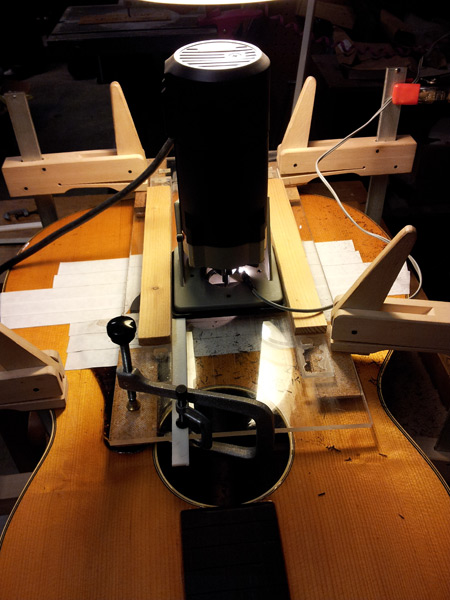

I've already routed the first 4 slots at this point, and am lining up the pass and depths stops for the next rout.

This is a contrast between the first 4 routs of the E, B, G, and D, vs. the remaining, untouched, 5th (A string) and 6th (low E string) slots.

The plugs have been shaped and glued. The fitting process is identical to fitting a new bone saddle except, modern saddles (with rare exceptions) are NOT glued in! The slots are just a lot shorter and made out of the same wood as the bridge itself... ebony.

The ebony plugs were sliced from the end grain of the donor stock, much like a lumberjack race, so that the direction of the grain (subtly visible) matches the grain direction of the bridge itself.

The plugs are sanded flush but unpolished as of yet.

The holes are reamed out, the edges beveled again, and the bridge is finish sanded, and polished. Barely a shadows worth of evidence of the procedure is visible.